Automation has led the entire medical device market on an exciting journey. Elos Medtech in Denmark works hard to become an automated factory and continuously initiates and completes projects in automation. One of our efforts has been to build a modular and automated packaging line to secure highest product quality and increase production efficiency. After two years of intense development, the line is now up and running.

Initiatives to meet the demands of tomorrow’s medical device market

Customers on the global medical device market are demanding higher production efficiency, better precision, highest product quality and traceability down to the smallest part. One way to achieve this is by adding automation to the processes of medical device manufacturing. Through Elos Medtech’s concept The Automated Factory, we have intensely focused on optimization, automation and robotics since 2012. One of our ongoing projects during this time has been to create an automated and modular production line. Our proof of concept resulted in a packaging line for prosthetic products for implants that are packed in blister packages.

Creating a better working environment with automation and robotics

Up until recently, we packed our prosthetic products for implants one by one with tweezers, in clean rooms, wearing masks and gloves. This process required unnecessarily long production time and monotonous work tasks. To increase production efficiency and create a better working environment for our employees we started looking at alternative solutions.

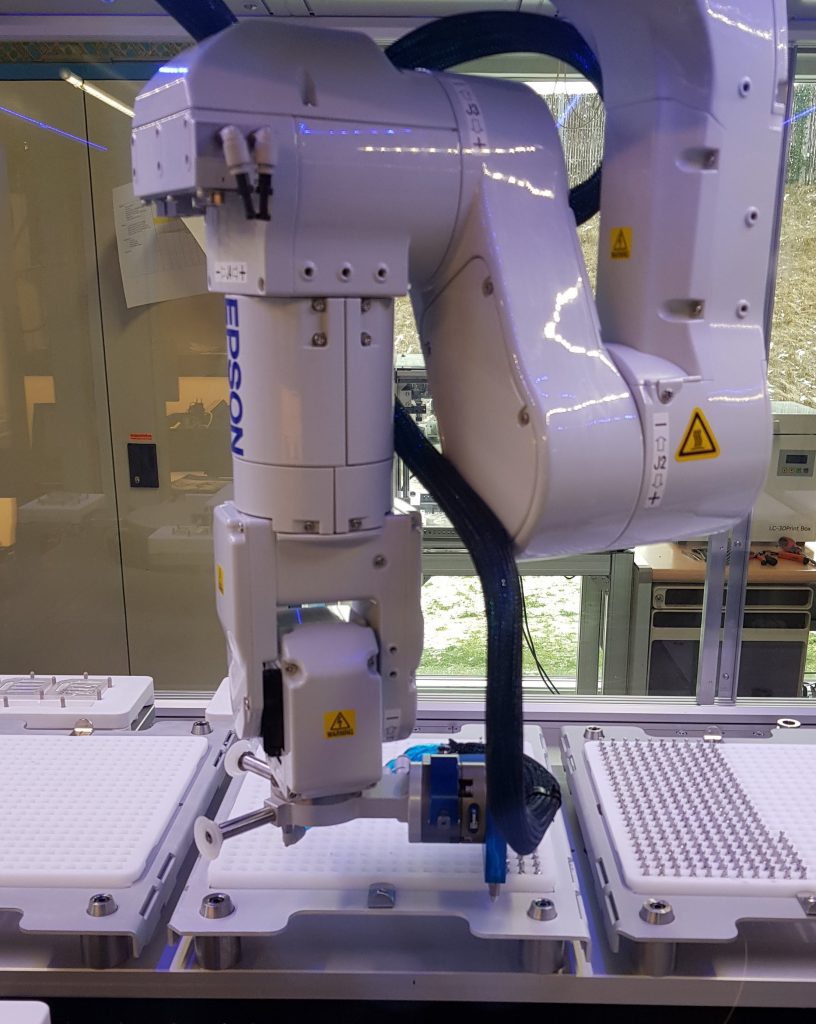

Having 300 different kinds of packages, it was not possible to buy one machine that could pack all variants. So, instead of having to invest in several different machines, we started developing our own modular system. By making the system modular we can use it for packing many types of products, but also for entirely different purposes such as assembly or validation of products. The operator should be able to easily change settings and tools of the system and thereby switch to another area of application.

A modular system to pack, assemble and validate medical devices

Our technical team started working with the concept five years ago, back in 2016, and the machine has now been up and running for a few weeks. As for now, the machine is calibrated to pack prosthetic products for two types of implants.

The process starts with the operator preparing the packaging line with papers, blister packs and products to be packaged before scanning the work order. The system will automatically make sure that the corresponding production program is set up correctly. It also controls that the right components and substances are available in the standardized fixtures and that the production cell holds the right temperature. After that, the machine will pack the products while collecting information about the process, which is then available to the operator whenever needed. This information includes, for example, production time, how many products that have been packed and if any product is damaged or disapproved for some reason.

A system built from scratch by Elos Medtech’s technical team

Because the whole system is built to be dynamically interchangeable, we are continually working to expand its capabilities beyond packing. Elos Medtech’s technical team has developed and programmed the entire system from its first line of code. This is highly valuable since we can do all changes and improvements by ourselves and it makes the process of adding functionality much smoother.

Moving towards a fully automated production process

By using automation to assemble, pack and validate our products we can offer our customers a more reliable and efficient production process. Also, our monitoring and control of the system improve the traceability and quality of our products. When we remove the process of packing products by hand, our production quality becomes more consistent and we improve the working conditions for our employees.

The development of this particular machine is just one part of everything that is being made through our concept The Automated Factory. We are moving towards a production line where few parts are touched by humans. Machines will do the repeatable and heavy labor tasks while our employees use their competencies for supporting innovation and progress. The technical team cooperates with machine operators and factory workers to recognize areas for improvement and implement these. This way, we will continue to develop our services and meet the ever higher demands of tomorrow’s global medical device market.

I hope you enjoyed reading this blog article! Would you like to know more about our projects in automation at Elos Medtech? Feel free to contact us. Also, don’t forget to visit our Knowledge blog for other interesting articles.